Bullion generally refers to gold and silver that is officially recognized as being at least 99.5% and 99.9% pure and is in the form of coins, barsand rounds.

Today, it is used as a store of value, and the purity of gold bullion is often assessed through the centuries-old technique of fire assay in conjunction with modern spectroscopic instrumentation to accurately determine its quality.

The bullion market is plays a role in various sectors including investors, central banks, and industrial uses of gold and silver, as it determines the pricing of these precious metals.

Bullion is traded in the commodities markets, which is primarily an OTC market open 24 hours a day. Investors can also buy a bullion futures contract, which is an agreement to buy or sell an asset or commodity at a preset price with the contract settling at a specific date in the future.

The manufacturing process of bullion involves several stages, starting with mining, then refining, and finally minting. Each stage is critical in transforming raw materials into high-purity gold and silver bullion or coins.

Mining

Gold and silver are found in ores, which are rocks or minerals that contain metal. Mining for gold and silver involves extracting these ores from the ground. This can be done through various methods including underground mining, open-pit mining, and placer mining. In underground mining, miners dig tunnels and shafts into the earth to reach the ore. Open-pit mining involves digging a large pit to reach the ore. Placer mining involves sifting through sand and gravel in river beds to find gold and silver.

Refining

Once the gold and silver ores are extracted, they must be refined to remove impurities and prepare them for sale. This may involve smelting, which is a process of heating the ore to a high temperature to melt the metal out of the rock. The molten metal is then poured into molds to form bars or ingots. Chemical refining may also be used to produce high-purity bullion. This involves dissolving the gold or silver in a chemical solution and then precipitating it out to form pure metal.

Minting

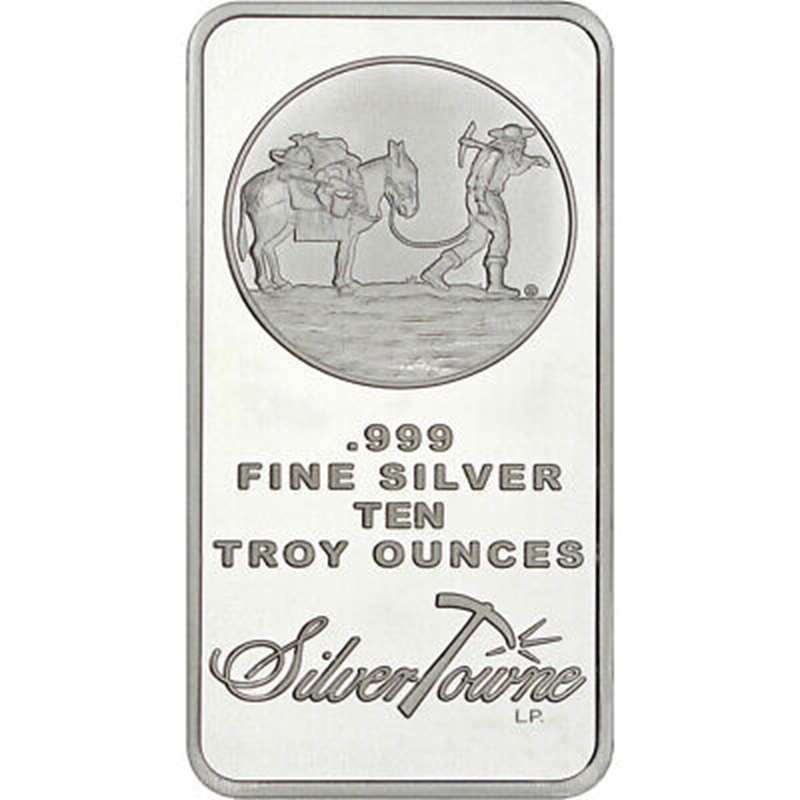

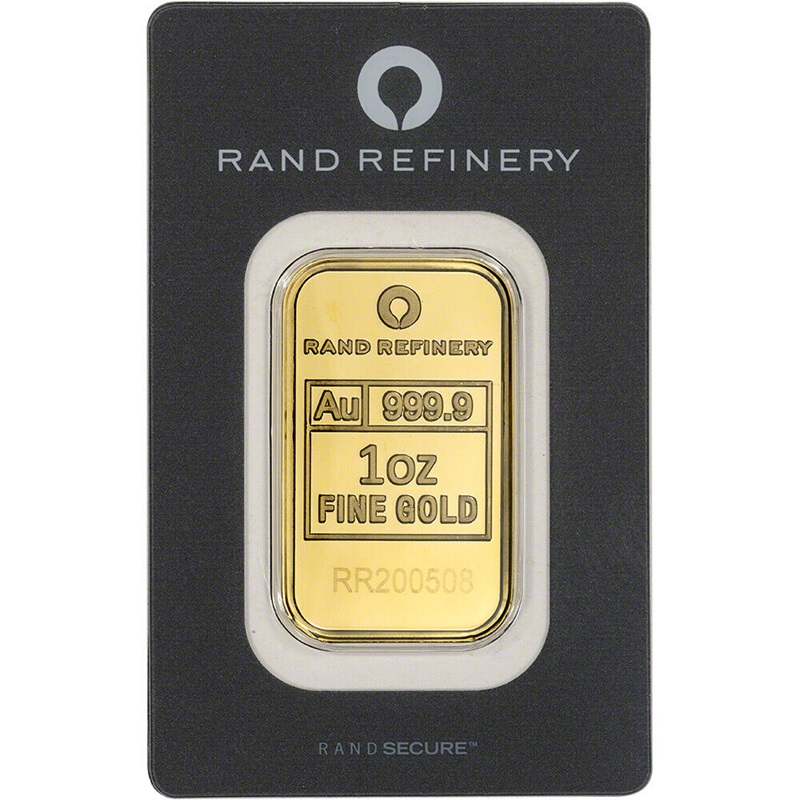

After the gold and silver are refined, they can be used to create bullion bars or coins. Bullion bars are typically made by casting the molten metal into molds. The bars are then stamped with the weight and purity of the metal. Coins are made by striking a blank piece of metal with a die that has the coin’s design on it. The force of the strike transfers the image onto the coin. The coins are then inspected and any that do not meet quality standards are melted down and the metal is reused.

Each of these stages requires specialized equipment and skilled workers. The process of manufacturing bullion is complex and requires a great deal of care to ensure the highest quality product.